The Procedures In The Tool Making Industry And The Importance Of Tool Makers

Tool making requires very high technical qualifications and keenness to quality and detail. For one to be able to produce tools of required standards, correct rules and regulations must be followed during the entire process. This is especially so because tools are the greatest essentials in the manufacturing industry and therefore influence the entire operations of the economy.

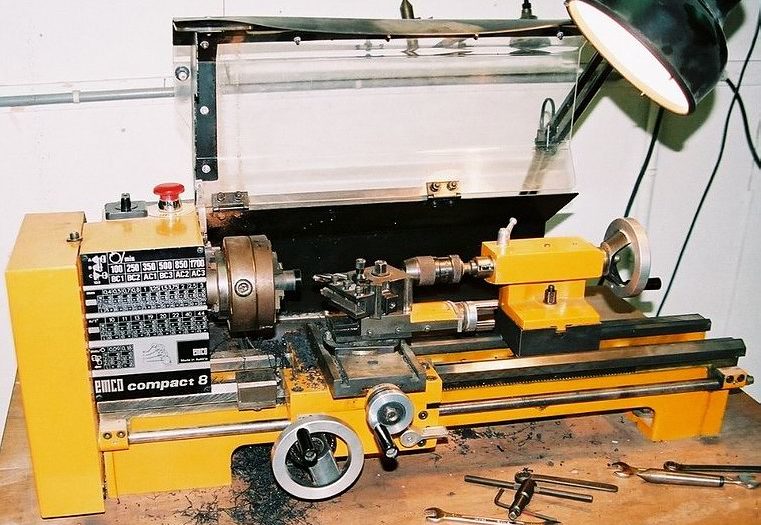

In the olden days, most tools were made by hand. Tool makers had to use tools like polishing machines, grinding machines and files to create a quality finish on their tools. This has however changed with time due to the introduction of numerically controlled milling, boring and grinding machines which make the tool making process easy and fast.

There is a need for a tool maker to be able to understand and interpret technical drawings of an end product which they intend to get. Operation of technical machines such as … Continue reading >>>