Digital Twin Technology in Automotive Manufacturing for Supply Chain Resilience

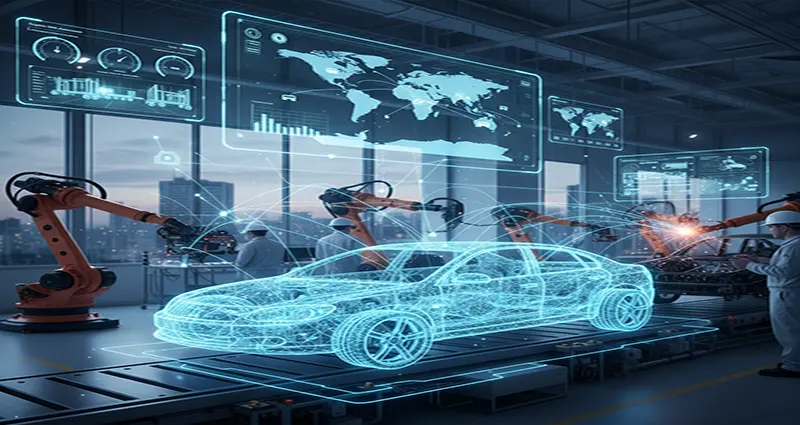

In the high-stakes world of automotive manufacturing, a single missing microchip or a delayed shipment of specialized steel can bring multi-billion dollar assembly lines to a grinding halt. As the industry shifts toward electric vehicles (EVs) and autonomous systems, the complexity of the global supply chain has reached a breaking point. Enter Digital Twin technology: the “resilience layer” that allows manufacturers to mirror their physical reality in a virtual world to anticipate, simulate, and survive disruptions.

The Architecture of Resilience: What is a Supply Chain Digital Twin?

A Digital Twin is not a static 3D model; it is a dynamic, living virtual representation of a physical asset, process, or system. In the context of the automotive supply chain, it creates a “digital thread” that connects raw material suppliers, Tier-1 component manufacturers, logistics providers, and the factory floor.

The Three Core Pillars:

- The Physical Entity: The actual trucks, warehouses, inventory,