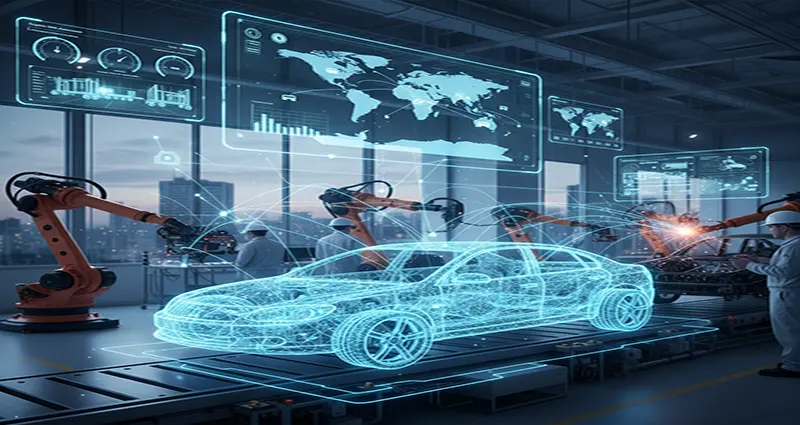

In the high-stakes world of automotive manufacturing, a single missing microchip or a delayed shipment of specialized steel can bring multi-billion dollar assembly lines to a grinding halt. As the industry shifts toward electric vehicles (EVs) and autonomous systems, the complexity of the global supply chain has reached a breaking point. Enter Digital Twin technology: the “resilience layer” that allows manufacturers to mirror their physical reality in a virtual world to anticipate, simulate, and survive disruptions.

The Architecture of Resilience: What is a Supply Chain Digital Twin?

A Digital Twin is not a static 3D model; it is a dynamic, living virtual representation of a physical asset, process, or system. In the context of the automotive supply chain, it creates a “digital thread” that connects raw material suppliers, Tier-1 component manufacturers, logistics providers, and the factory floor.

The Three Core Pillars:

- The Physical Entity: The actual trucks, warehouses, inventory, and assembly robots.

- The Virtual Replica: A high-fidelity model that simulates the behavior of the physical world using physics-based equations and AI.

- The Bi-directional Data Link: Sensors (IoT), GPS, and RFID tags that feed real-time data from the physical world into the virtual model, while the model sends back optimized instructions.

Strengthening the “Triple-A” Supply Chain

According to industry frameworks, Digital Twins bolster the three critical dimensions of a modern supply chain: Agility, Adaptability, and Alignment.

1. Agility: Real-Time Crisis Management

When a port closes or a supplier experiences a fire, traditional systems take days to assess the impact. A Digital Twin allows managers to run “what-if” scenarios in seconds. By simulating thousands of variables—from alternate shipping routes to part substitution—manufacturers can pivot before the disruption reaches the factory gate. Recent data suggests that companies using digital twins can improve their response time to exceptions by up to 60%.

2. Adaptability: Stress-Testing the Future

Automotive cycles are long. Digital Twins enable “stress-testing” of the supply network against long-term threats like geopolitical shifts or climate-related logistics failures. By modeling the entire ecosystem, OEMs (Original Equipment Manufacturers) can identify “single-point-of-failure” suppliers early and diversify their sourcing strategy.

3. Alignment: Breaking Information Silos

The “bullwhip effect”—where small fluctuations in consumer demand cause massive ripples of overstock or shortages—is a perennial automotive headache. Digital Twins provide a “single version of the truth” accessible to all stakeholders. When a Tier-2 supplier updates its production capacity, the Digital Twin reflects this immediately across the entire network, ensuring that the OEM and logistics partners are perfectly aligned.

Key Applications in the 2026 Automotive Landscape

As we move into 2026, several specific use cases have emerged as the “gold standard” for the industry:

| Application | Description | Impact |

| Predictive Logistics | Uses GPS and weather data to predict arrival times with 95% accuracy. | 20% reduction in expediting costs. |

| Virtual Factory Planning | Simulates assembly line changes for new EV models before moving a single machine. | 40% faster time-to-market. |

| Inventory Optimization | Dynamically adjusts safety stock levels based on real-world risk scores. | 10-15% reduction in carrying costs. |

| Tier-N Visibility | Maps the sub-tiers of the supply chain to detect hidden risks in raw material sourcing. | Enhanced ESG compliance and risk mitigation. |

Overcoming Implementation Barriers

Despite the clear advantages, building a “resilient twin” is not without its hurdles.

- Data Silos & Interoperability: Integrating data from legacy ERP systems and thousands of different suppliers remains the biggest technical challenge.

- The “Cost of Complexity”: While the ROI is high, the initial investment in IoT infrastructure and high-compute cloud platforms can be a barrier for smaller Tier-2 and Tier-3 suppliers.

- Security & Privacy: Sharing real-time production data across a network raises concerns about intellectual property theft and cybersecurity.

Case Study: BMW and the “Virtual-First” Approach

BMW has famously adopted a “virtual-first” strategy, using Digital Twins to simulate entire factory layouts in collaboration with NVIDIA’s Omniverse. This allows them to plan supply rhythms down to the second. By the time a physical part arrives at the loading dock, its digital counterpart has already been “processed” through the virtual line a thousand times, ensuring that zero-hour disruptions are virtually eliminated.

The Future is Synchronized

Digital Twin technology is no longer a luxury for “early adopters”; it has become a prerequisite for survival in a volatile global economy. By transforming fragmented, lagging data into a real-time, interactive map, automotive manufacturers are building supply chains that don’t just withstand shocks—they learn from them.

In the coming years, we expect to see these twins evolve from predictive (what will happen?) to prescriptive (what should we do?), with AI agents autonomously rerouting shipments and adjusting production schedules in real-time.