Top-Rated Salvage Yards for Quality Used Auto Parts

When it comes to repairing or restoring a vehicle, finding quality used auto parts can make a significant difference in both performance and budget. Salvage yards, also known as junkyards or auto recyclers, can be treasure troves for car enthusiasts and mechanics seeking reliable and affordable spare parts. Here are some of the top-rated salvage yards renowned for their quality inventory of used auto parts:

ABC Auto Salvage:

With a vast selection of used auto parts ranging from engines and transmissions to body panels and accessories, ABC Auto Salvage has established a reputation for providing top-notch parts at competitive prices. Their knowledgeable staff and organized inventory system make finding the right part a breeze.

Greenway Auto Parts:

Specializing in environmentally friendly auto recycling, Greenway Auto Parts offers a wide range of quality used parts for various makes and models. Their commitment to sustainability and customer satisfaction has earned … Continue reading >>>

Affordable Electric Vehicles with Fast Charging: Embracing Sustainability and Convenience

As the world shifts towards a more sustainable future, electric vehicles (EVs) have emerged as a key player in reducing carbon emissions and promoting cleaner transportation. For many consumers, the affordability and convenience of owning an electric vehicle with fast charging capabilities are essential factors in making the switch from traditional gas-powered cars. Here are some affordable electric vehicles that offer fast charging options, making eco-friendly transportation accessible and efficient:

1. Chevrolet Bolt EV

The Chevrolet Bolt EV has gained popularity as an affordable electric vehicle with fast charging capabilities. With a range of over 200 miles per charge and DC fast charging compatibility, the Bolt EV offers a practical and sustainable option for everyday commuting. Its spacious interior and advanced technology features make it a compelling choice for those looking to embrace electric mobility without breaking the bank.

2. Nissan Leaf

The Nissan Leaf is a well-known electric vehicle … Continue reading >>>

Luxury Car Rentals for Special Occasions Near Me

Renting a luxury car for a special occasion can add an extra touch of elegance and sophistication to your event. Whether it’s a wedding, prom, anniversary, or any other memorable celebration, opting for a luxury car rental can elevate the experience and create lasting memories. If you’re looking to rent a luxury car for a special occasion in your area, here are some top-rated rental services to consider:

1. Exotic Car Collection by Enterprise

Known for offering a wide range of luxury and exotic vehicles, the Exotic Car Collection by Enterprise is a popular choice for those seeking upscale car rentals for special occasions. With a diverse selection of premium cars from brands like BMW, Mercedes-Benz, and Porsche, this rental service provides an opportunity to indulge in luxury without the long-term commitment.

2. Hertz Dream Collection

The Hertz Dream Collection boasts a portfolio of high-end luxury cars, making it an … Continue reading >>>

Top-Rated Dealerships for Used Luxury Cars

Purchasing a used luxury car can be an exciting venture, offering the opportunity to drive a high-quality vehicle at a more affordable price point. When it comes to finding the best dealership for used luxury cars, there are several key factors to consider, including reputation, selection, and customer service. Here are some top-rated dealerships renowned for their exceptional offerings in the realm of used luxury cars:

1. CarMax

CarMax is a well-known national chain of used car dealerships that has garnered praise for its extensive inventory of used luxury cars. With a focus on transparency and providing a no-haggle, upfront pricing model, CarMax has become a favorite among buyers seeking a wide selection of luxury vehicles, including brands like Mercedes-Benz, BMW, and Audi.

2. Off Lease Only

Off Lease Only has earned a strong reputation for its comprehensive inventory of high-end used cars, including luxury models from top manufacturers. Their … Continue reading >>>

Where to Find Affordable Used Car Engines Near Me

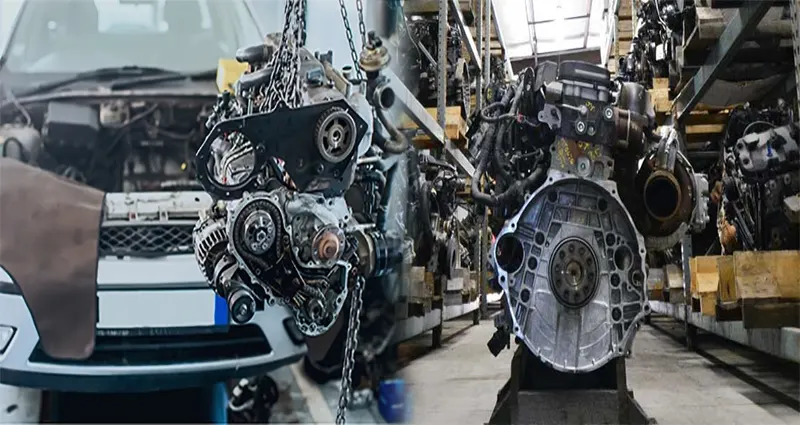

If you are in need of a replacement engine for your vehicle, buying a used car engine can be a cost-effective solution. However, finding affordable and reliable used car engines can be a challenge. Here are some tips on where to find affordable used car engines near you:

1. Local Salvage Yards

One of the most common places to find used car engines is at local salvage yards or junkyards. These facilities often have a wide variety of vehicles from which to salvage parts, including engines. Visiting salvage yards in your area or contacting them by phone can help you locate a used engine that fits your car model at a reasonable price.

2. Online Marketplaces

With the rise of online marketplaces, finding used car engines has become more accessible. Websites such as eBay, Craigslist, and Facebook Marketplace often have listings for used engines from individual sellers or auto dismantlers. … Continue reading >>>