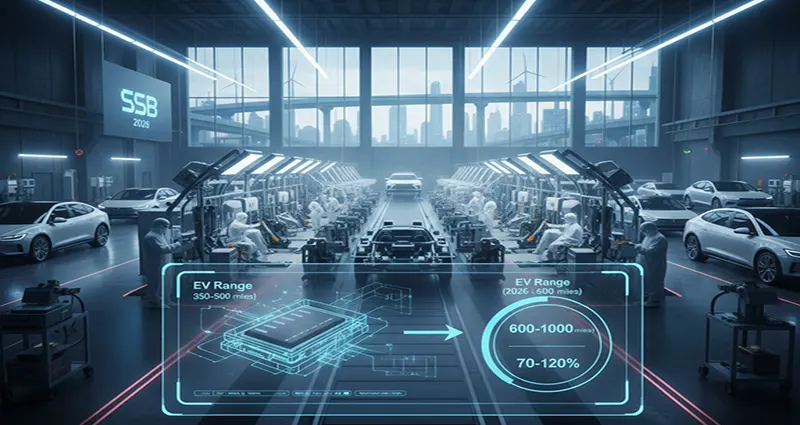

For over a decade, the “solid-state battery” has been the elusive holy grail of the automotive world. In 2026, the narrative has shifted from laboratory speculation to factory floor reality. With the first commercial production lines now operational and high-profile debuts at CES 2026, the industry is witnessing a fundamental recalibration of what an electric vehicle (EV) can achieve.

The transition from liquid electrolytes to solid-state chemistry isn’t just an incremental upgrade; it is a “regime change” for energy density. By replacing flammable liquids with solid ceramic or polymer separators, manufacturers are finally breaking the range barriers that have constrained the first generation of EVs.

The 600-Mile Threshold: A New Industry Standard

In the era of lithium-ion, a 300-mile range was considered the “sweet spot” for premium EVs, while 500 miles was a rare and expensive outlier. In 2026, solid-state production has pushed the ceiling to 600–750 miles (1,000–1,200 km) for flagship models.

Why the Range Jumps So Significantly:

- Energy Density Doubled: Standard lithium-ion batteries typically hover around 250–300 Wh/kg. New 2026 solid-state cells from pioneers like Donut Lab and Factorial Energy are hitting 400–500 Wh/kg. This allows twice the energy to be stored in a pack of the same weight.

- Lithium-Metal Anodes: Solid electrolytes enable the use of pure lithium-metal anodes instead of graphite. Lithium metal is far more efficient at storing ions, drastically reducing the physical volume of the battery.

- Reduced Cooling Requirements: Liquid electrolytes are sensitive to heat and require heavy, complex liquid-cooling systems. Solid-state batteries are inherently more stable, allowing engineers to strip away hundreds of pounds of cooling hardware and replace it with more battery cells.

Real-World Performance: Extreme Temperatures and “Zero Taper”

One of the most profound impacts of the 2026 production rollout is how “range” is defined in difficult conditions. Historically, EV range would plummet by up to 30% in freezing winters.

- The Winter Breakthrough: 2026 solid-state packs, such as those used by Verge Motorcycles and prototypes from GAC, report over 99% capacity retention at -30°C. For a driver in Scandinavia or Canada, a “600-mile range” finally means 600 miles all year round.

- Charging Without the “80% Wall”: Standard batteries slow down (taper) their charging speed significantly after reaching 80% to prevent damage. Solid-state technology allows for “Zero Taper” charging, meaning a car can maintain peak charging speeds all the way to 100%. This effectively adds another 20% of “usable” long-distance range that was previously too slow to access at a public charger.

The 2026 Leaders: Who is Winning the Race?

While many expected the “Big Auto” giants to lead, the 2026 landscape is a mix of agile startups and aggressive Chinese manufacturers.

| Company | 2026 Status | Headline Spec |

| Donut Lab / Verge | Production (Q1 2026) | 400 Wh/kg; 5-minute full charge. |

| GAC (Guangzhou Auto) | Pilot Production | 1,000 km (621 mi) theoretical range. |

| Toyota | Pilot / Small-scale | 1,000 km range; 10-minute 10-80% charge. |

| Factorial Energy | Real-world Validation | 745+ miles achieved in Mercedes-Benz EQS tests. |

| QuantumScape | Pilot (Eagle Line) | High-cycle life; entering GWh scale production. |

The Payload Paradox: Lighter, Not Just Longer

For the first time, solid-state production is allowing manufacturers to choose between “Extreme Range” or “Extreme Efficiency.”

Not every driver needs 700 miles of range. For the mass market, the impact of 2026 production will be felt in the creation of lighter vehicles. By using a solid-state pack that provides 300 miles of range but weighs half as much as a current battery, manufacturers can produce EVs that handle better, accelerate faster, and—most importantly—cost less to run due to reduced tire and brake wear.

Challenges: The Cost of the “Holy Grail”

Despite the 2026 breakthroughs, solid-state batteries remain the “platinum tier” of the market.

- Manufacturing Yields: While production has begun, the “yield rate” (the percentage of batteries that come off the line without defects) is still lower than that of mature lithium-ion plants.

- Price Premium: In early 2026, a solid-state EV remains roughly 20–30% more expensive than its liquid-electrolyte counterpart.

- Mass-Market vs. Flagship: Most 2026 solid-state deployments are currently limited to flagship luxury SUVs, performance motorcycles, and high-end sports cars.

The End of Range Anxiety

The year 2026 marks the beginning of the end for “range anxiety.” As solid-state production scales, the conversation is shifting from “Will I make it to the next charger?” to “When was the last time I even thought about charging?”

With 600-mile ranges becoming achievable and 10-minute charging becoming the norm, the solid-state revolution of 2026 has finally made the EV experience indistinguishable from—and in many ways superior to—the internal combustion engine.